17 4 Stainless Steel Vs 316

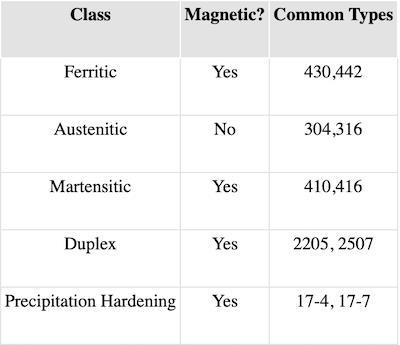

Precipitation hardening grade is a combination of two stainless steel structures i e.

17 4 stainless steel vs 316. 17 4 comparable to 302 304 is desgined mainly for high strength with some corrosion resist tbuelna aerospace 2 dec 14 23 12 more details about the application where these parts were used over the 3 year period would be helpful especially some photographs. 17 4 and 316l stainless steel. But it isn t 316 and you re not quite sure why that matters but you have a piece of paper in front of you that says it does so go on and elaborate. When you compare stainless steel 17 4 ph vs 316 it is obvious that 17 4 ph has higher hardening content.

17 4 ph vs 316 offer high corrosion resistance. This article will focus on two types in particular. The numbers 17 4 refer to its composition. The 17 4 ph stainless steel is magnetic and less corrosion resistant than 316l stainless steel.

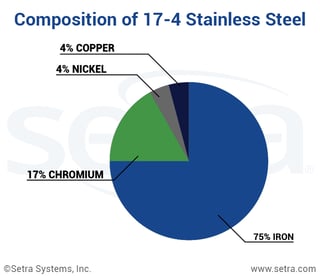

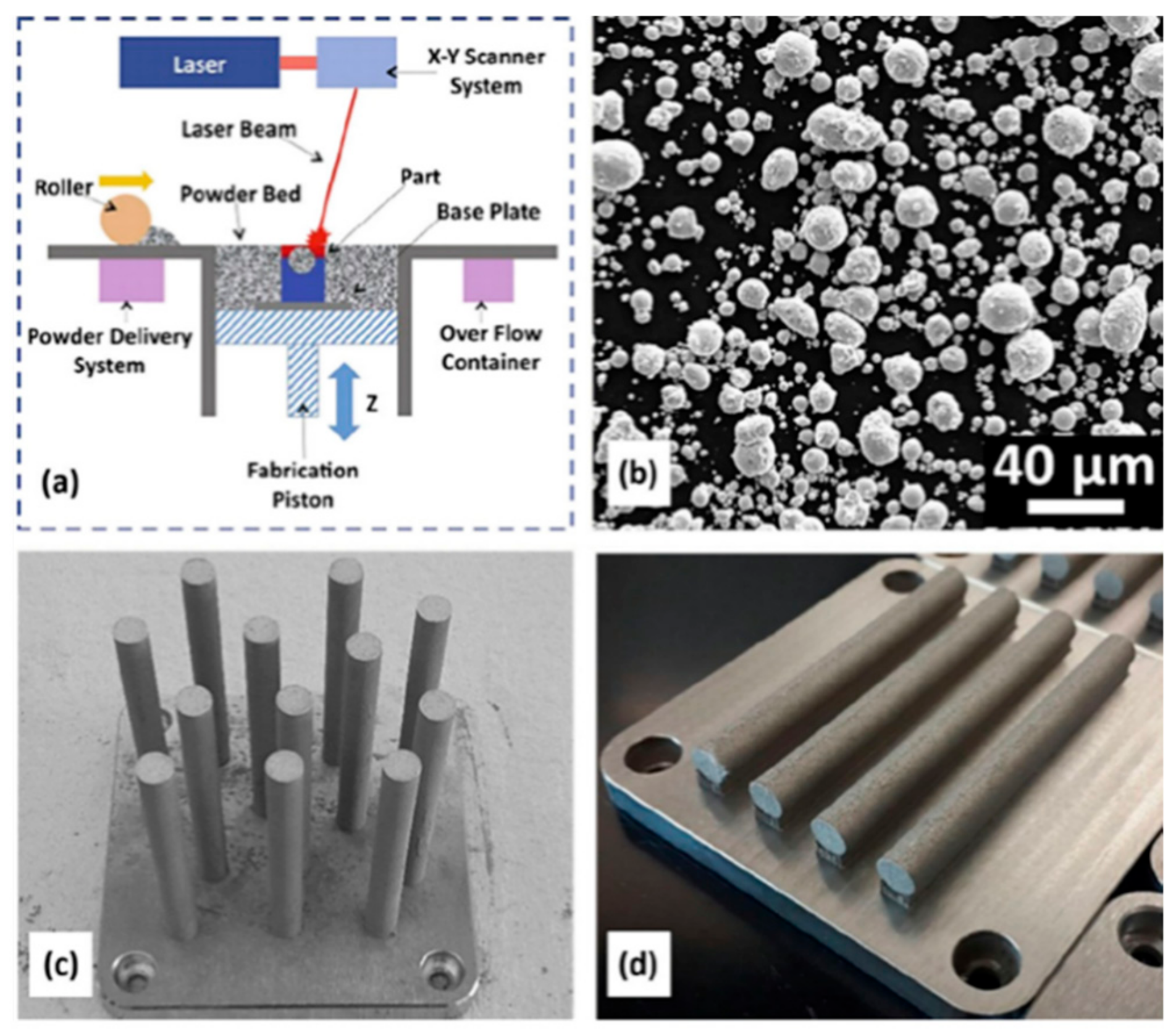

One distinguishing factor are the 17 4 ph shafts. Ss316 and 17 4 ph are common used two types of stainless steel grades for investment casting. 17 4 stainless steel also known as sae type 630 is a common and exceptionally durable type of steel used in a diverse variety of industries and applications. 17 chromium and 4 nickel.

Standard 316l is slightly magnetic but non magnetic versions are available. Almost at any condition the corrosion resistance for 316 is better than 17 4.

%20vs%20SS%20316(18-10%20Stainless%20steel).jpg)