17 4 Ph Stainless Steel Microstructure

This paper deals with the investigation of the microstructure and wear behavior of the stellite 6 cladding on precipitation hardening martensitic stainless steel 17 4ph using gas tungsten arc welding gtaw method.

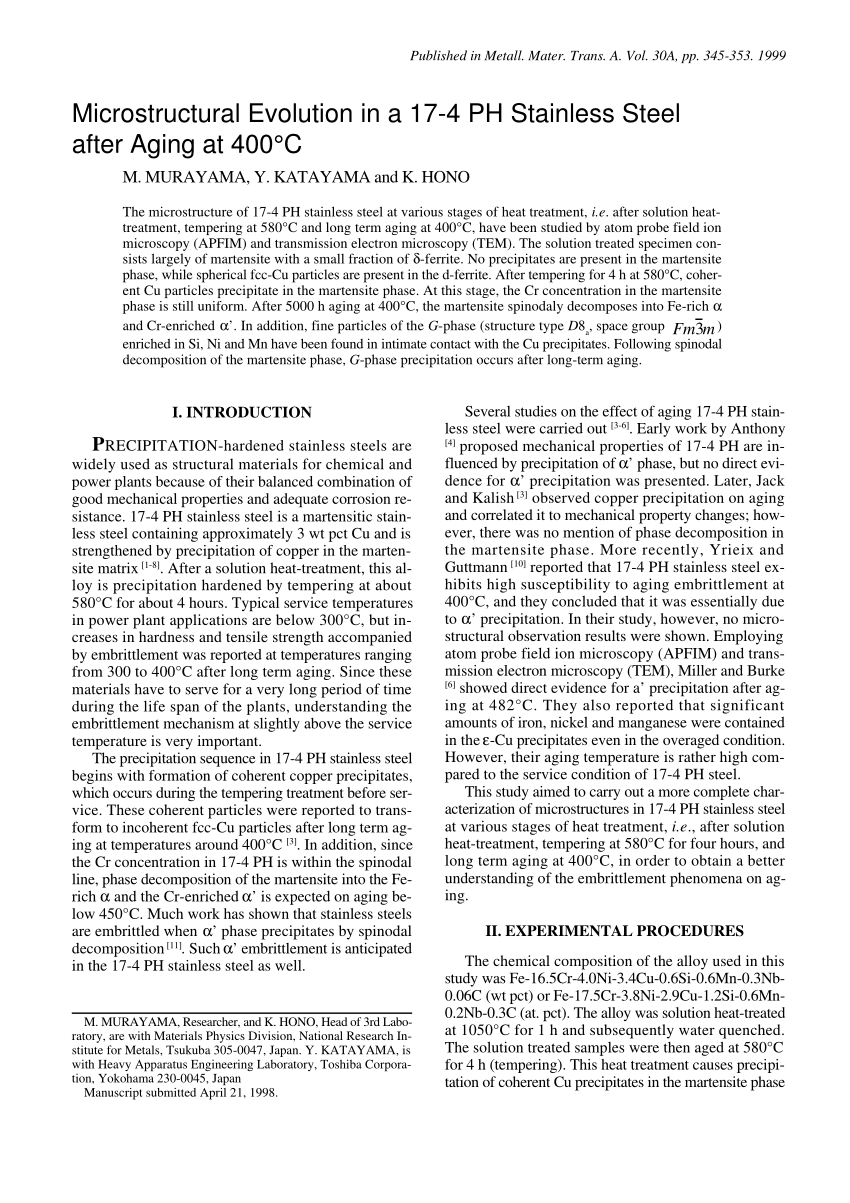

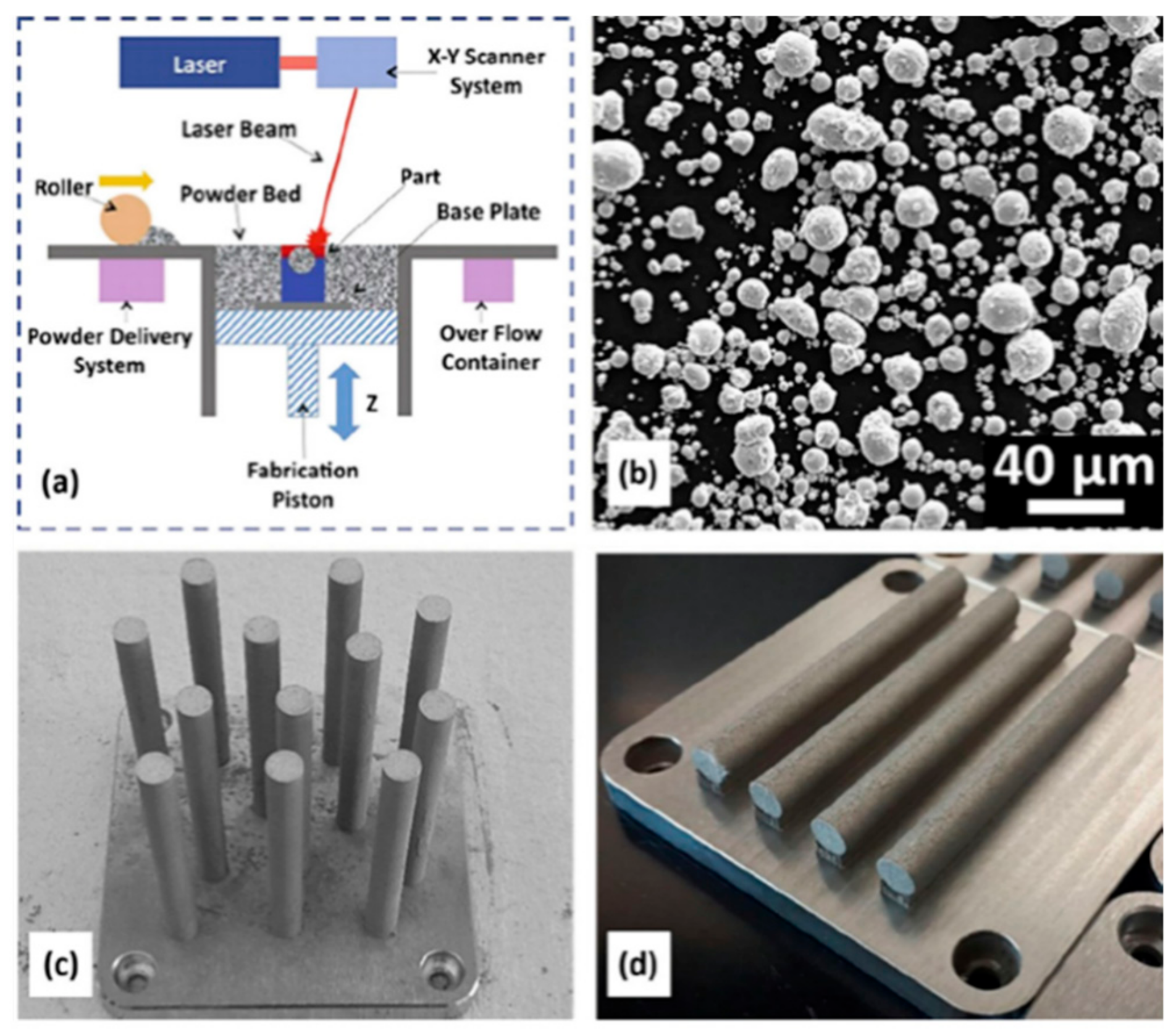

17 4 ph stainless steel microstructure. The corrosion resistance of alloy 17 4ph is comparable to 304 stainless steel in most environments and is generally superior to the 400 series stainless steels. Bayode esther t akinlabi member iaeng and s. 1 a selective laser melting schematic and pre alloyed atomized powders. Precipitation in 17 4 ph stainless steel begins with coherent bcc cu rich.

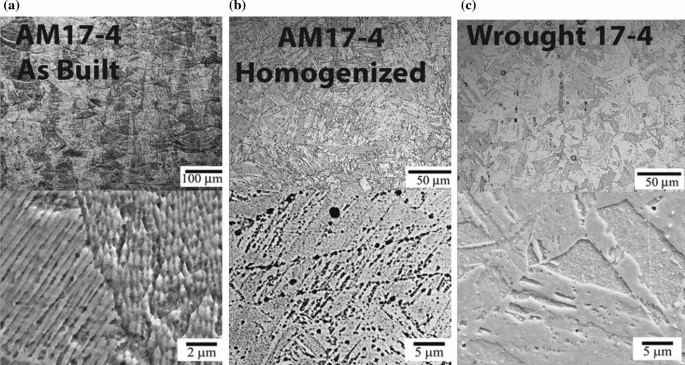

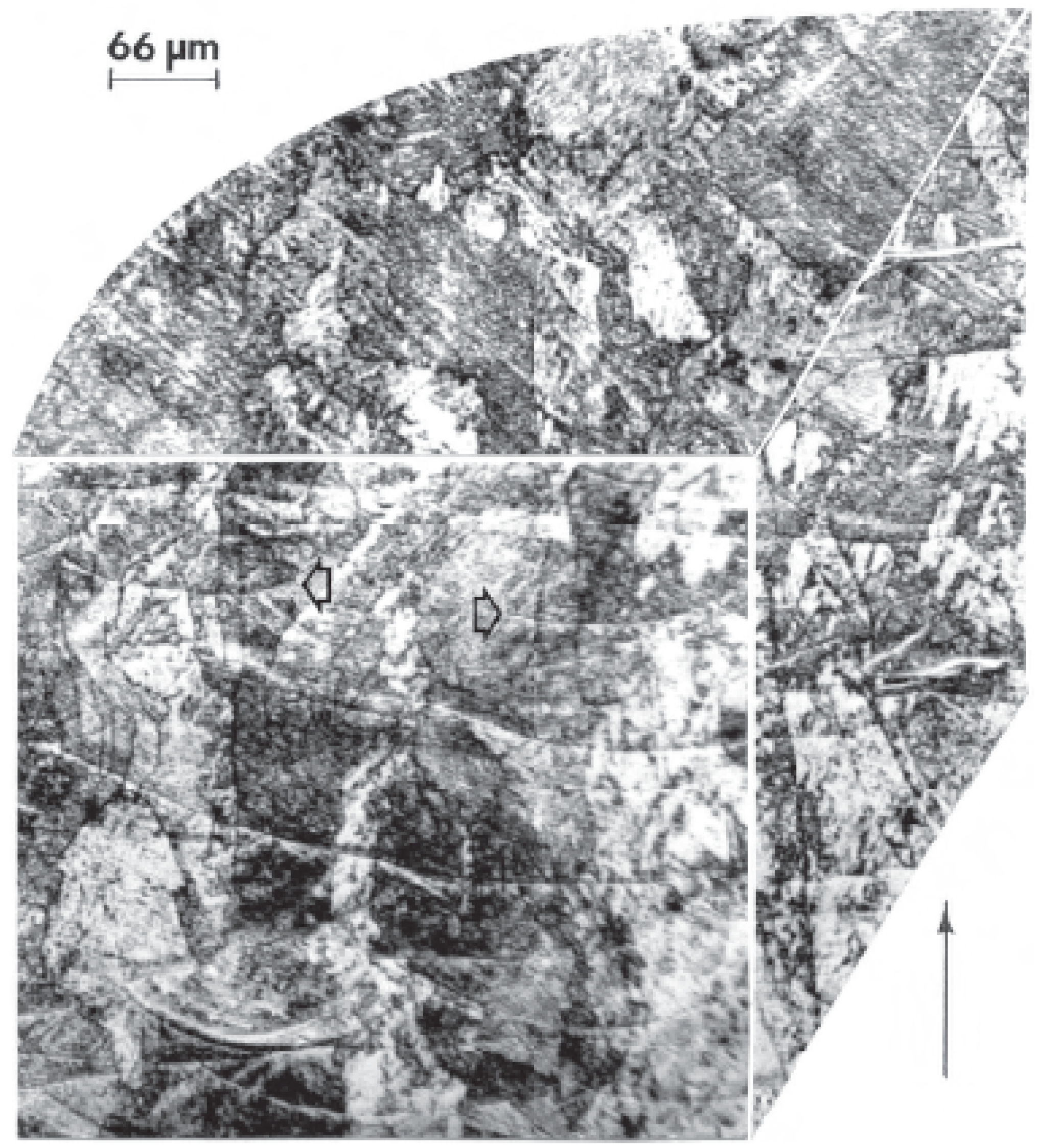

168 murr et al. The microstructure was martensitic with a. The 17 4 ph stainless steel that was used in the experiment was obtained according to ams 5604. In b ar and c n 2 482ºc for 1 h after solution treatment.

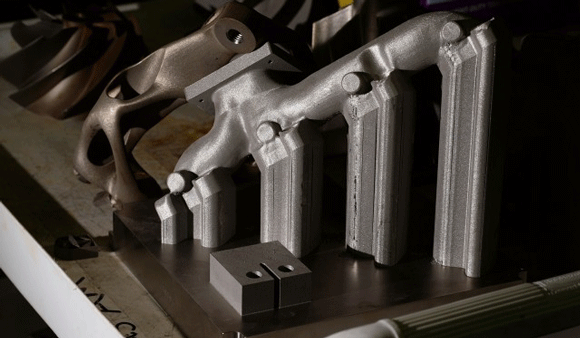

Stainless steels are widely used in a variety of applications such as food processing petrochemical plants and transportation industries due to their high strength and good corrosion resistance. Study on the microstructure and mechanical properties of 17 4 ph stainless steel depending on heat treatment and aging time. Microstructure and microhardness of 17 4 ph stainless steel made by laser metal deposition. To homogenize the metal the standard heat treatment was used.

It is also known as 630 stainless steel. The indentation results showed that the sample subjected to the lower energy density did not respond well to the conventional heat treatment on 17 4ph stainless steels as expected. Wrought 17 4 ph steel condition a. 17 7 ph precipitation hardening alloys when choosing an alloy for a particular project it may be helpful to determine your criteria.

Gas tungsten arc welding gtaw was used to cladding of 17. 17 4 ph stainless steel is widely used in oil and gas industries.