15 5 Ph Stainless Steel Mechanical Properties

This is also called the solution heat treated condition or condition a.

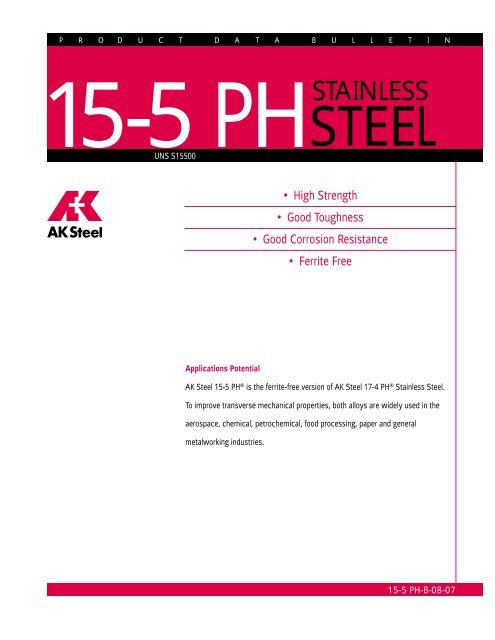

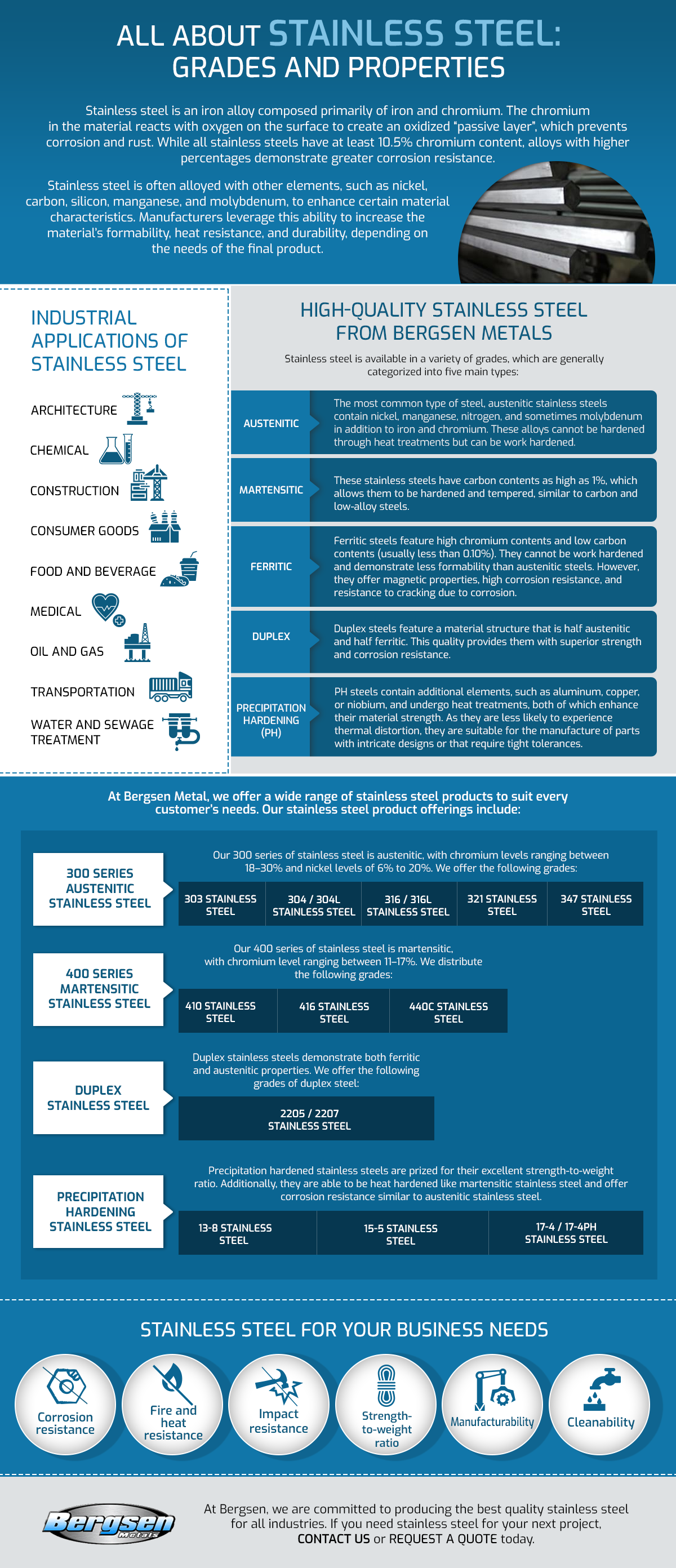

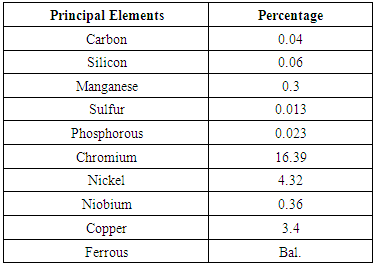

15 5 ph stainless steel mechanical properties. Exell 15 5 ph was developed by ellwood specialty steel as a premium quality mold steel exell 15 5 ph is a martensitic precipitation hardening stainless steel with certain advantages over conventional stainless mold steels some of these characteristics include. Ak steel 15 5 ph is the ferrite free version of ak steel 17 4 ph stainless steel. Stainless steel 15 5 ph also known as xm 12 or uns s15500 is a modification of 17 4 ph developed in the 1960s. Corrosion resistance good mechanical properties at temperatures up to 600 f 316 c and good toughness in both the longitudinal and transverse directions in both base metal and welds.

15 5 ph stainless steel 15 5 ph stainless steel is a martensitic precipitation hardening type stainless steel. 15 5 ph stainless steel mechanical properties ak steel 15 5 ph stainless steel provides excellent mechanical properties. Alloy 15 5 is used in applications that require high transverse strength and toughness such as engine parts. 15 5ph download 15 5ph spec sheet.

Annealing is conducted by heat treating at approximately 1900 f 1040 c to 1950 f 1065 c and cooling to room temperature. Ati 15 5 precipitation hardening stainless steel flat roll product is produced in the annealed condition. Introduction chemical composition mechanical properties manufacturing process applications. It also offers excellent transverse notch toughness ductility and very good uniformity of properties.

Type 15 5 ph is a martensitic precipitation hardening stainless steel that provides high strength good corrosion resistance good mechanical properties at temperatures up to 600 f 316 c and good toughness in both the longitudinal and transverse directions in both base metal and welds. In addition it is more cost effective than many high nickel non ferrous alloys. 15 5 uns s15500. Typical mechanical properties achieved for 15 5 ph after solution treating and age hardening are given in the table on the attached page.

Both alloys are widely used in the aerospace chemical petrochemical food. Weldability precipitation hardening steels can be readily welded using procedures similar to those used for the 300 series of stainless steels. It possesses all the advantages of 17 4 ph including single low temperature thermal treatment. Applications potential 15 5 ph stainless steel offers a combination of high strength and hardness good corrosion resistance plus excellent transverse mechanical properties.

For applications requiring high strength and hardness plus corrosion resistance this alloy is an outstanding choice. Exell 15 5 ph stainless mold steel. Short time low temperature heat treatments minimize distortion and scaling. The mechanical properties in larger sections and forgeability are superior to that of.